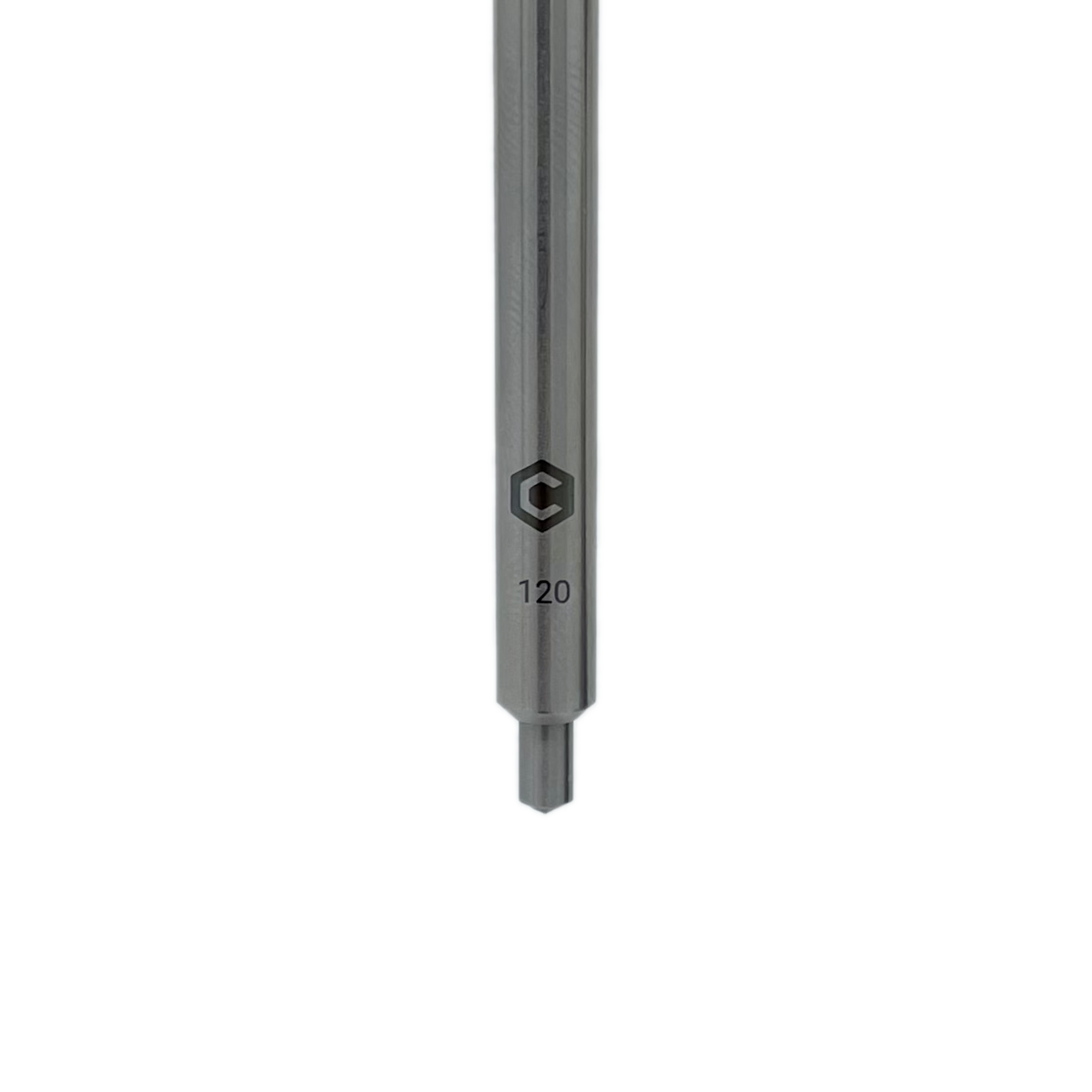

MC Etcher - Diamond Drag Bit

$ 40.00

Please select all options.

MC Etcher is our new diamond drag bit. It is perfect for fine line engraving on composites, metals, and glass.

MC Etcher drags a diamond-coated, spring-loaded tip over the surface of your material to create an etched or engraved pattern, it does not cut with flutes like a normal endmill.

IMPORTANT: The drag engravers are not meant to rotate so the spindle needs to be turned off when using MC Etcher.

Ships in a reusable storage tube.

Details

MC Etcher is available in three variants:

- Individual 90-degree tip

- Individual 120-degree tip

- Combo pack: 90-degree tip (1 ea) and 120-degree tip (1 ea)

All MC Etchers have a 1/4" Shank.

90 Degree or 120 degree tip?

The 90-degree tip has better penetration in very hard or anodized materials.

The 120 deg tip provides slightly wider lines in softer materials such as fiberboard but has less penetration in harder materials.

Recommended Diamond Drag Bit Speeds and Feeds

We've tried the MC Etcher with a variety of materials and we don't find a lot of difference between the speeds and feeds that work for each material. We recommend these as a starting point:

- Feedrate: 60 in/min

- Plungerate: 30 in/min

- Cut Depth / Compression: .015"

Drag Bit Toolpaths

You have a couple of options to generate a toolpath for a drag engraver:

- Use Carbide Create, or any other 2D CAM program, to generate contour toolpaths and pocket toolpaths with an RPM of zero (or leave your spindle turned off).

- Use the Engrave toolpath in Carbide Create Pro to generate outline and fill toolpaths for drag engraving.

Materials

What materials will MC Etcher work with?

- Plastics like acrylic, plexiglass, and polycarbonate

- Metals like aluminum, brass, or stainless steel

- Glass, porcelain, and ceramics

- Stone tile, like granite and marble

Note: The life of MC Etcher will vary depending on the materials that it's asked to engrave. For instance, softer materials, like plastics, cause very little wear while harder materials, like glass and stone, can cause much higher wear.

If you are using MC Etcher to engrave hard materials, it's worth doing a test to find the minimum toolpath density (or the maximum stepover) that will give you the look that you're trying to achieve. This will help extend the life of MC Etcher as much as possible.