-

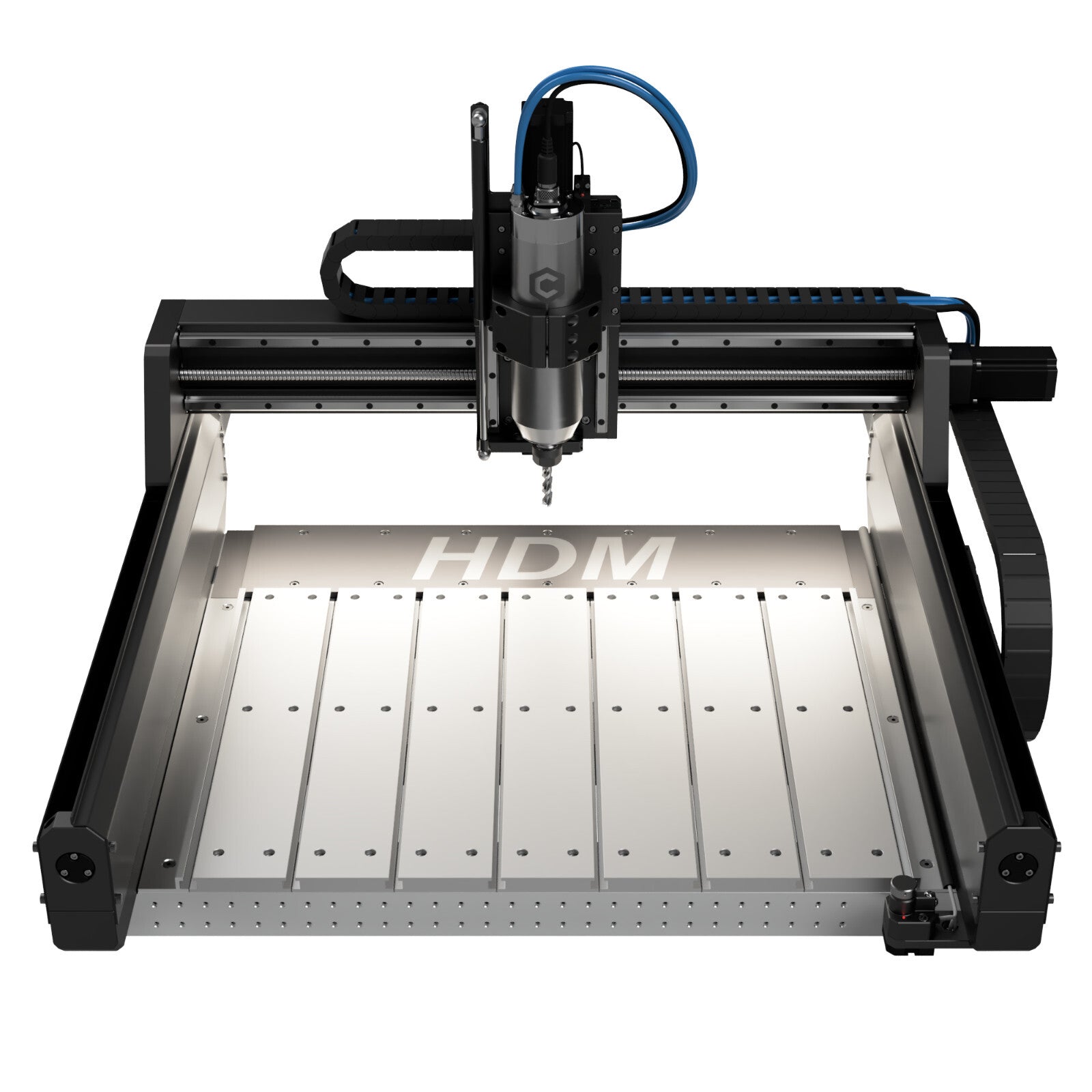

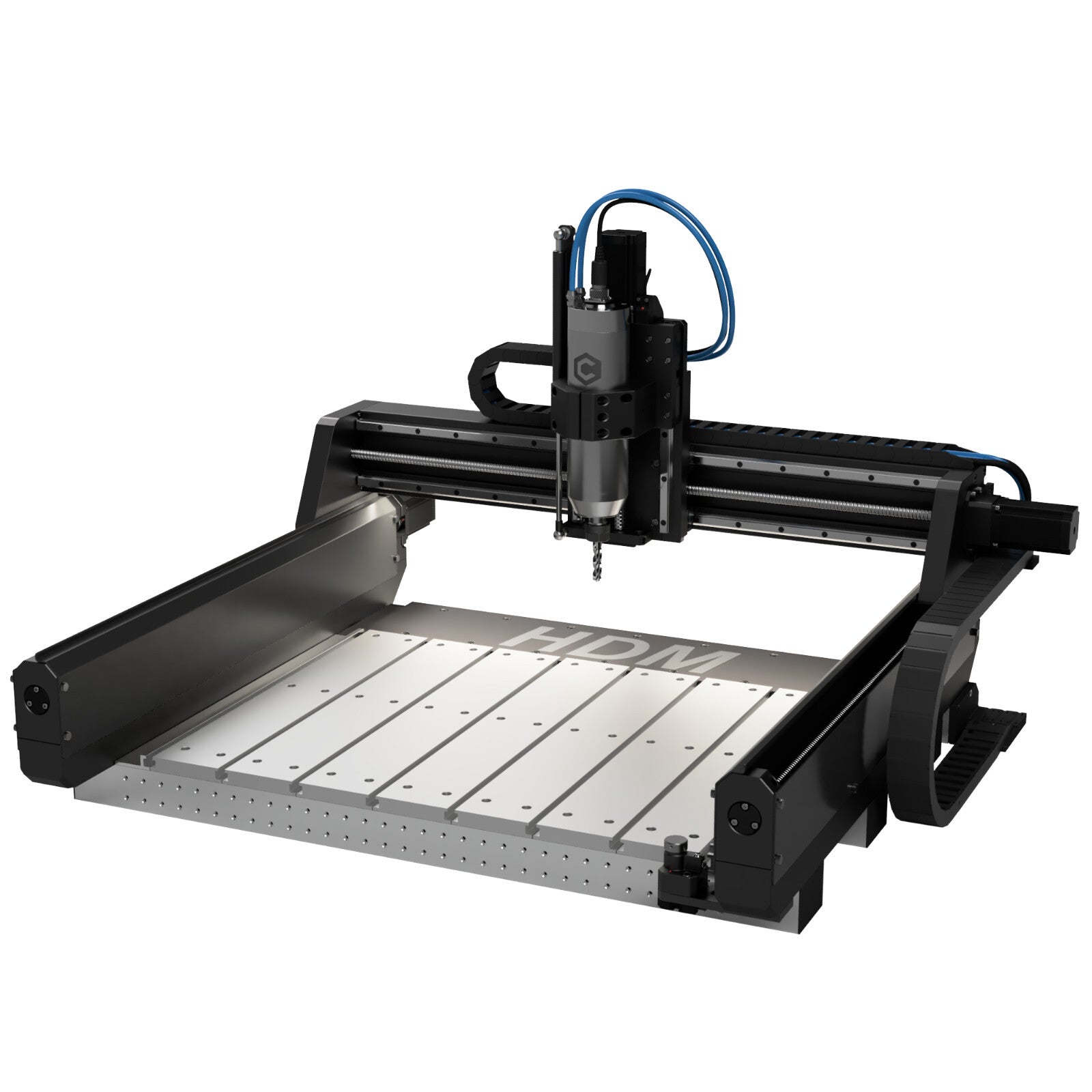

The Shapeoko HDM is the result of years of prototyping and testing. It didn't come easy, we had to build and throw away more prototypes than we care to admit but the results are worth it. Shapeoko HDM cuts wood and non-ferrous metals (aluminum and brass) with ease and accuracy. The HDM will run all day long without breaking a sweat.

Let's start with the hardware:

- All-aluminum Hybrid Table with T-slot workholding

- Threaded holes on the front of the machine for edge-machining

- Heavy-duty custom extrusions

- HG-15 linear bearings on every axis

- 16mm ball screws on every axis

- Custom ball screw wipers on X and Y-axis

- 4-pole 80mm water-cooled spindle with VFD control and chiller (110 or 220V)

- LED lighting under the gantry

The Frame

Starting from the bottom, we have our Hybrid Table. We've written about our Hybrid Table at length on our blog if you want deeper detail but the bottom line is that the Hybrid Table gives you flexible workholding for your projects and a rigid base for the machine itself. It's the core of all of our newest CNC routers. For the HDM V3, we made a special all-aluminum version of the Hybrid Table based on customer requests.

Moving higher up, the rest of the machine is built from a new set of aluminum extrusions that we made for the Shapeoko HDM. The extrusions took a couple of attempts to get right but we think they turned out really well. The extrusions are cut to approximate length at the extruder and then we machine them in-house and have the gantry anodized locally. The result is an accurate and precise extrusion that also looks great.

At the end of each extrusion, we have precision-machined aluminum end plates that are up to 30mm thick.

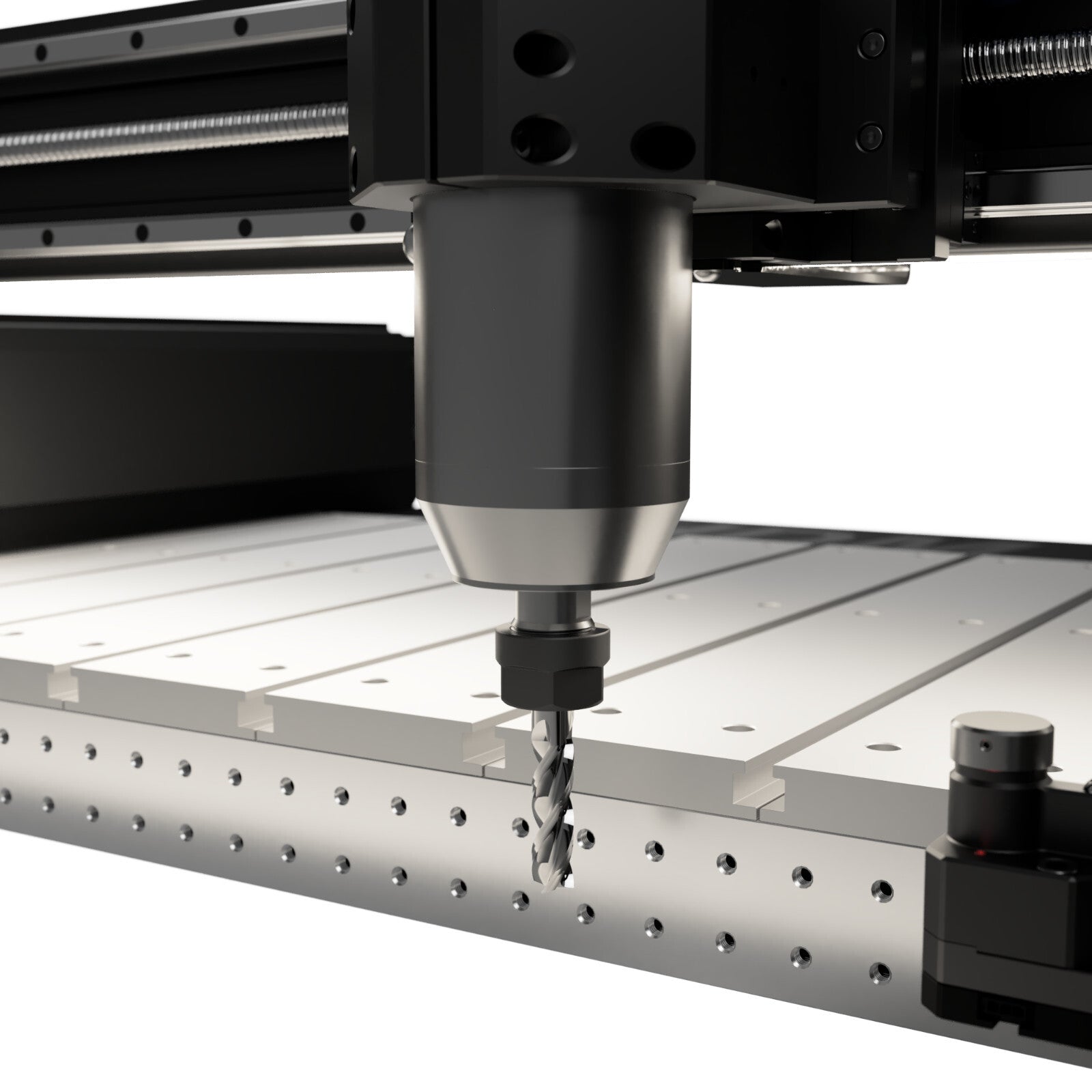

Motion system

Shapeoko HDM uses HG-15 linear bearings and 16mm ballscrews for motion. Technically, the HG-15 linear bearings are way too much for a CNC router of this size, but we don't think you'll mind. We machine the extrusions that the linear rails mount to in-house for maximum precision and accuracy. We don't use T-slots and T-nuts for precision motion hardware.

Our ballscrews have custom-made wipers that provide additional protection against dust and dirt. The ballscrews are kept in place by dual angular contact bearings for a combination of rigidity and low friction.

When taken together, this motion system lets you deliver all of that spindle power into the cut with minimum deflection and backlash.

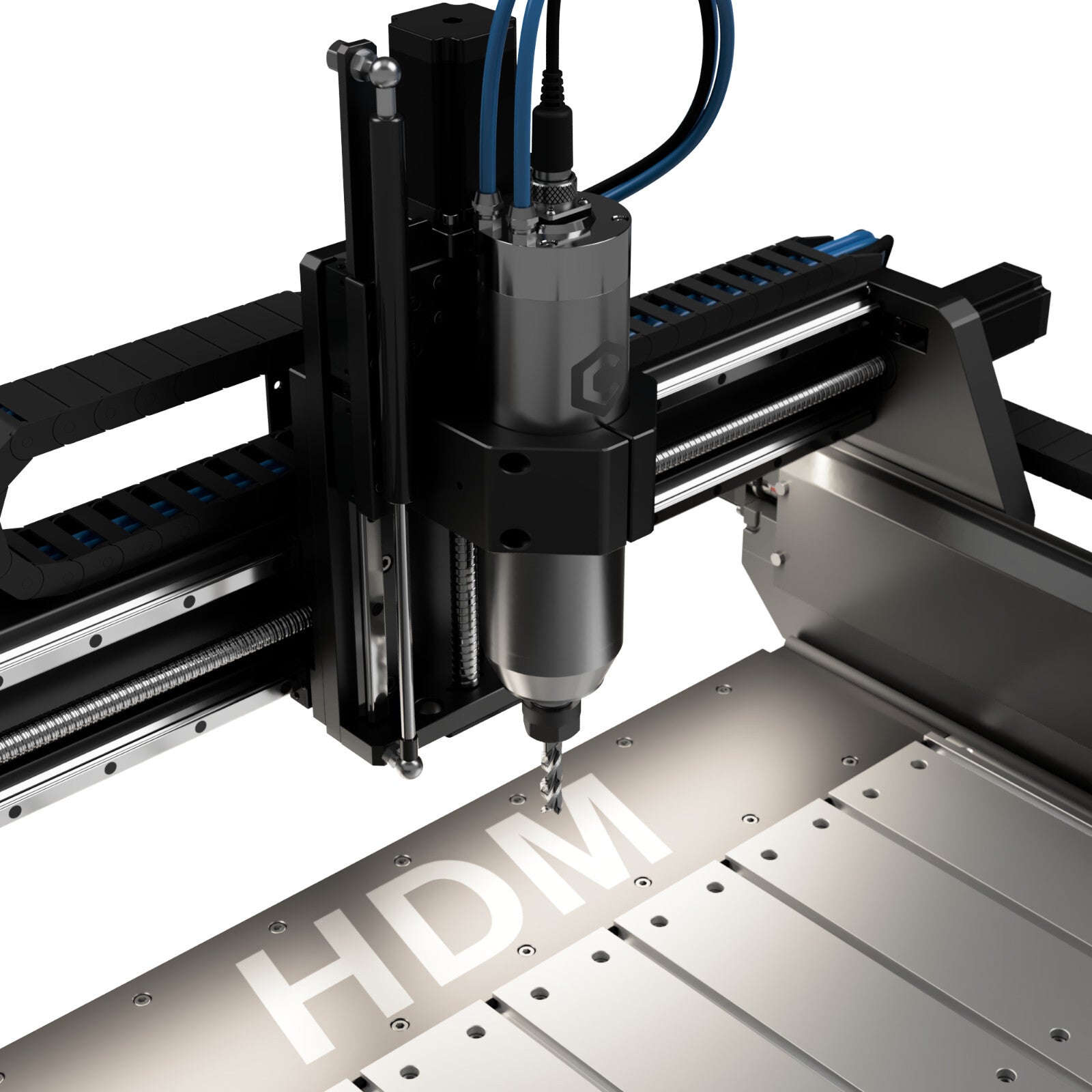

80mm VFD Spindle

For the Shapeoko HDM, we use a water-cooled 80mm spindle controlled by a VFD (variable frequency drive) with an RPM range of 8k to 24k. The 110v version outputs approximately 1.5kW and the 220v version outputs 2.2kW.

We designed a custom VFD interface board that does a couple of things:

- Set the spindle RPM based on your G-code. You won't need to turn the spindle on or off or set the RPM.

- Filter the AC power lines to reduce the electrical noise that can leave the VFD and spindle and get into the AC supply lines.

The spindle is water-cooled and includes a CW-3000 spindle chiller to constantly circulate coolant through the spindle during use.

The spindle uses ER-20 to hold cutters up to 1/2" (13 mm). Technically, an ER-20 collet can hold a larger cutter but we don't recommend anything over 1/2".

Shapeoko 5.1 Pro vs. Shapeoko HDM

Shapeoko 5.1 Pro Shapeoko HDM Target Use High-value productivity Maximum precision and performance Build Focus Optimized for value and capacity No compromises on accuracy or component quality Cutting Area Up to 4x4' Smaller footprint, but extremely rigid and refined Materials Wood, plastics, light metals Wood, plastics, aluminum, brass Assembly Partially assembled kit Fully assembled, aligned, and tested in-house -

Specifications

Travel and Size X-Axis travel 690mm (27in) Y-Axis travel 610mm (24in) - 75mm is over the front of the machine Z-Axis travel 145mm (5.7in) Table Width (X) 795mm Table Depth (Y) 539.5mm Z Clearance (From table to gantry) 145mm Machine Width 1063mm Machine Depth 961mm Weight 120kg Spindle Spindle RPM 8k - 24k Spindle Power 1.5kW (110V) / 2.2kW (220V) Spindle Collet ER-20 Coolant 9 liters Max tool diameter 13mm (1/2") Run out 0.01mm Feed rates Rapid traverse (X/Y/Z) 5000 mm/min Max cutting feed rate (X/Y/Z) 5000 mm/min Power requirements 220V Version 2 x 110V outlets for spindle chiller and motion electronics + 220V outlet, 12 amp for spindle 110V Version 2 x 110V outlets for spindle chiller and motion electronics + 110V outlet, 15 amp for spindle -

What's included

- Shapeoko HDM V3

- 4-pole 80mm Spindle + VFD

- CW3000 Spindle chiller

- Sweepy 80mm dust boot

- Teez-Nutz (Qty 12)

- Shapeoko Essentials Clamps (Qty 6)

- #201 .25" endmill

- 0.125" ER-20 collet

- 0.25" ER-20 collet

- 0.50" ER-20 collet

- Collet wrenches

- HDM version of BitSetter

- Carbide Motion control software

- Carbide Create 2D CAD/CAM software (works with any CAD/CAM software)

- 4, 30 minute 1-on-1 training sessions with a Carbide 3D expert via video chat

- 12-month warranty

- 60-day Mistake Are On Us Guarantee

What you need to provide:

- 9 liters of antifreeze for the spindle chiller

Computer Requirements:

- OS/X 10.14 or higher

- Windows 10 or 11, 64-bit (Intel or AMD)

-

Warranty and Support

One-Year Warranty

Shapeoko comes with a one-year warranty against defects. If you have any problems, we’ll take care of them.

See our warranty here.

60-Day, "Mistakes are On Us" Guarantee

We want you to jump into your new Shapeoko CNC router without any fear of damaging anything so our warranty includes the following benefit:

For the first 60 days that you own your Shapeoko, we’ll replace any Carbide 3D-branded item that’s damaged, even if it’s your fault.

Details about what's covered can be found here.

1-on-1 Training

We want you to be successful with your Shapeoko CNC router. That’s why we offer 4, 30-minute 1-on-1 training sessions with a Carbide 3D expert via video chat. We’ll help you get your Shapeoko up and running, answer any questions you have, and help you get started with your first project.

Details can be found here.

Unlimited US-Based Support

If you need help, we are available via:

- Phone

- Video Chat

- Contact us here.

-

Shipping

Shapeoko HDM ships fully assembled via freight. It will take a couple of people (or other creative rigging) to get the Shapeoko HDM from the pallet to the table you plan to put it on.

We only ship the Shapeoko HDM to the US and Canada. For other countries, we recommend the Shapeoko 5.1 Pro, which is available in most countries.